The Hacker International HTD Rotating System is designed and built as an efficient and economical compliment to drilling rigs utilizing a top drive drilling system. Whether a rig build or a retrofit to an existing rig, the Hacker HTD can be designed to fit any application, any size, and is engineered for the most rugged drilling conditions. Hacker International is world renowned for its custom built rotary tables which are being utilized on every continent in the world. We pride ourselves in our innovative designs and our ability to solve specific needs of our customers in each custom rotating system we build.

The new line of HTD Rotating Systems incorporates many of our features that have proven the test of time along with new concepts in the elimination of mud contamination. The sealed units virtually eliminate mud flow through the spindle/cover area, the locking device points of entry, and also through the centralized maintenance door. A fully enclosed and sealed hydraulic motor is designed for continuous use or as the need arises with rapid response console features and can be purchased with a complete hydraulic control system or by the component. By connecting the hydraulic drive directly to the rotating system drive we have eliminated transmission and drive train issues, which has resulted in a smaller, lighter and more cost effective design.

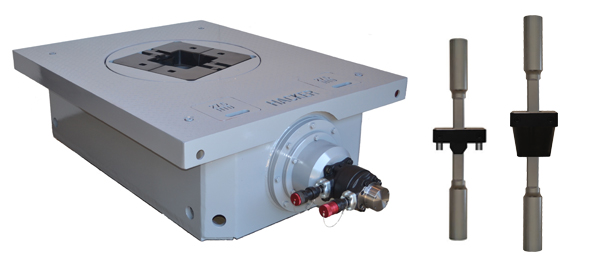

The new HTD units are available in sizes 49.5”, 37.5”, 27.5”, 22.5”, 20.5”, and the ever popular 17.5”. Custom built units are also available for 15”, 12.5” and 10.5” rotating systems. Hacker also sells any type of bushings required to satisfy our customers’ needs.

With a maximum torque of 25k ft. lbs., a rotating speed of 135 rpm’s and with a static load rating of 1250 tons, our 27.5” table is a brute able to withstand harsh drilling conditions but easily controlled by the movement of a joy stick. These high torque variable speed features make this rotating system the perfect complement to your top drive system.

All of our tables are equipped with precision machined spiral bevel gears and heavy duty main thrust bearings to provide long lasting durability. The dual locking system utilizes ratcheting lock pawls that engage the rim of the table assembly. This enables the table to be locked in a single direction or both directions. The entire pinion shaft assembly uses a sealed cascade lubrication system from a large oil reservoir.

When the need arises to rotate your drill string during routine maintenance or short time repair, pick up the Hacker HTD rotating tool, connect it to your string, drop it in your square or pin drive master bushing, and your rotating while repairs and maintenance are being performed on your top drive. The new rotator systems are available in any thread configuration.

All Hacker Rotating Systems are field-proven, efficient and reliable giving our customers many years of reliable service. And if repairs are needed for any of your drilling rig components don’t hesitate to call us 24/7. Our fully staffed component repair facility and fabrication shop has a 30 ton lifting capacity with 25 feet under hook clearance.

Be sure to ask us about our electric drive systems, hydraulic locking devices, and optional rails for various iron roughnecks, and power slip installation.

|